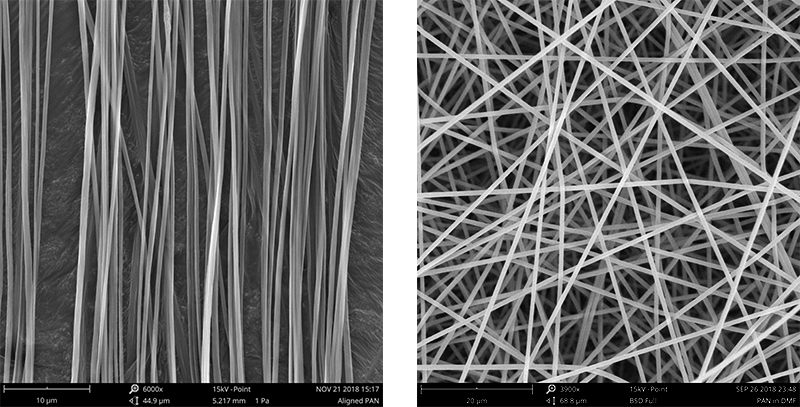

这popularity of the electrospinning technique continues to grow, and advances in technology are making the workflow easier and more precisely controllable. One important factor to control when processing electrospun fibers is their orientation as they are collected. The two main fiber orientations obtained during electrospinning are aligned (图1A) and random (图1B)。While random fibers are randomly oriented in different angles throughout the collected sample, aligned fibers are typically oriented in the same direction.

平板和滚动收集器是最常用的无编织,随机,电纺微纤维和纳米纤维的收集工具。这些随机导向的纤维提供了高表面积,这对许多应用(例如过滤和脱盐)有益,其中提供了更多的接触点,因此可以从过滤的培养基中有效去除污染物或盐。188金宝搏app安卓下载随机定向的纤维也可用于血管组织工程,因为它们的结构模仿天然组织,从而增强细胞生长。但是,随机定向的纤维不适合某些专门应用,例如生成神经导管。188金宝搏app安卓下载神经细胞在对齐的电纺结构上具有更好的迁移率和增殖。排列的纤维取向还可以通过增加拉伸强度并防止样品拉长来增强机械性能。该原理的一种应用是对齐纤维围绕着血管移植的圆周轴。这些排列的纤维将防止样品显着扩展,并使样品在临床上足以防止爆发压力。

这most efficient, and increasingly common method of collecting aligned fibers is by using a rotating drum collector (Figure 2a)。这degree of fiber alignment is determined by the linear speed of the rotating collector. As linear speed increases, fibers become more aligned. Linear speed on a rotating collector is calculated by![]() ,,,,and is typically represented in revolutions per minute (rpm), where

,,,,and is typically represented in revolutions per minute (rpm), where= linear velocity,

= radius of drum collector, and

= angular velocity (Figure 2b)。A rotating drum with a 10 cm diameter operating at 500, 1,000, and 2,000 rpm will generate a linear speed of 2.62, 5.24, and 10.47 m s-1, 分别。20厘米的鼓将在RPM一半的一半处达到相同的线性速度。

b)在计算线性速度时要考虑变量的图(

To demonstrate the effects of changes in linear velocity on fiber alignment, a 10 cm drum collector was used to collect electrospun polycaprolactone (PCL). PCL was selected for this example due to its extensive use in tissue engineering and drug delivery applications. Rotating speed was varied while all other electrospinning conditions were kept constant. When the drum was set to 500 rpm, the collected fibers had random orientation with an average diameter of 3.44 µm (Figure 3a)。随着旋转速度增加到1,000 rpm(Figure 3b) and 1,500 rpm (Figure 3c),观察到向对齐纤维的过渡,纤维直径仅略有变化。在2,000 rpm处(Figure 3d)高线性速度将纤维拉伸到对齐状态,并将纤维直径降低至2.75 µm。注意如何随着RPM的增加观察孔长度的增加;需要在控制孔长度时牢记的关键方面。

图4显示了纤维orientat的定量分析ion on all PCL electrospun samples from Figure 3. Parameters for the analysis were: a distribution of 0 to 180°, a bin size of 5° and 750 measurements performed per sample. As expected from Figure 3a, when the rotational speed was only 500 rpm (图4a), fibers did not have enough linear speed to stretch into aligned orientation. This resulted in an average frequency of aligned fibers below 40 across the sample. When the speed was slowly increased to 1,000 rpm (图4b) and 1,500 rpm (图4c),纤维取向逐渐向90°转移。在2,000 rpm处(图4d) there was a much tighter distribution of aligned orientations between 85° and 95°, reaching a peak frequency of 160.

a)在500 rpm处(

当增加旋转鼓的线性速度收集对齐的纤维时,可能会产生风/空气湍流,这可能会影响样品收集过程中的纤维方向。这液体andSpinboxinstruments are designed so an opposite charged voltage is applied in the collector. This improves the electric field between the needle tip and the collector, which mitigates turbulence issues and allows fibers to properly deposit with desired alignment. If processing parameters meet certain specifications, this electrical bias can also create what are known as super aligned fibers. Though super aligned fibers were thought to be difficult to generate in large quantities via electrospinning, they are now necessary structures for some applications and can be repeatably generated using the液体orSpinboxsystems. The structural and mechanical properties of super aligned fibers are critical for applications such as: batteries, nerve conduit tissue engineering, filters, textiles, and sensors.

In biomedical and pharmaceutical applications, super aligned polyhydroxybutyrate (PHB) fibers are useful because they are highly biocompatible and biodegrade easily. Figure 5 shows the workflow used to obtain a sample of super aligned electrospun PHB. These super aligned fibers were made with theFluidnatek le-100静电系统(Figure 5a)。Figure 5bshows the super aligned electrospun PHB deposited onto a 20 cm drum in the LE-100.Figure 5cshows the super aligned sample after removal from the drum collector, andFigure 5d是一个SEM图像,显示了超排列的PHB纤维的微观结构(Fd= 4.48 ± 0.39 µm).

为了在使用Fluidnatek或Spinbox系统时实现所需的纤维取向,在样品沉积过程中要优化的关键参数是:旋转鼓收集器的直径,鼓的线性速度和电气偏置。无论您是生成随机导向的纤维以改善过滤属性,还是创建对齐纤维以优化机械性能,Fluidnatek和Spinbox系统都可以简化工作流程并提供批处理到批量的再现性。

纤维方向对机械性能具有很大的影响,并将根据应用需求和进行测试影响样本行为。例如,当使用缝合力保留强度(通常用于血管评估的机械测试)时,对齐的纤维将具有最小的力,但是当实施应力应变拉伸测试时,较高的力。因此,所有人Fluidnatek系统are engineered to be used up to 2,000 rpm as a standard offered accessory, achieving a linear speed up to 20.94 m s-1,,,,with higher speeds achievable upon request.图6shows our液体LE-500 system根据RPM的使用,旋转的鼓准备收集随机和对齐的纳米纤维。